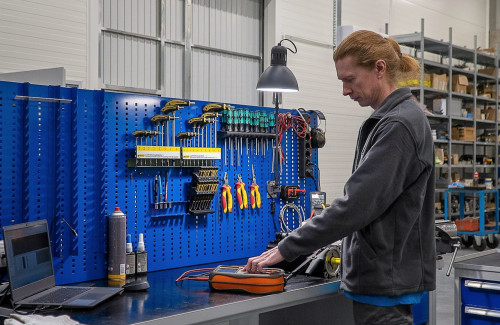

Electric motor repairs

Comprehensive repair of electric motors for industry

ADEGIS Automation Service offers repair and regeneration of electric motors for the industrial sector. We perform a wide range of repair activities, including: dynamic rotor balancing, replacement of bearings and measuring transducer, repair of brakes and mechanical faults, renovation of the paint coating.

We specialize in servo motor repairs: we have our own testing facilities for servo motors from most well-known manufacturers.

We provide a free service estimate, efficient order processing and a 24-month warranty for the entire device. If necessary, we perform express repairs or on-site repairs (in Poland).

REMINDER: Our offer is aimed at businesses. We do not provide services to individual clients.

How to repair an electric motor in ADEGIS?

- Contact us via the inquiry form or your regional representative.

- Send us your device for a free repair estimate.

- Accept the time and price offer that we will present to you.

Scope of work for motor repairs

Scope of work for repairs of asynchronous electric motors, DC motors, servo motors:

- measuring the condition of winding insulation

- cleaning, drying, impregnation of windings

- dynamic balancing of the rotor

- replacement of bearings

- stator rewinding

- rotor rewinding (commutator replacement)

- brush replacement

- brake regeneration: cleaning, brake adjustment / replacement of the friction disc

- measuring the braking torque

- regeneration of bearing seats

- shaft regeneration (crooked shaft, damaged spline, worn shaft surface)

- replacement of the power and signal socket

- testing the measuring transducer (encoder/resolver/tachogenerator / Hall sensors)

- replacement of the measuring transducer

- positioning the measuring transducer

- motor sealing

- renovation of the paint coating

- motor test on the drive

If the extent of the damage does not allow for effective repair, we follow a strict no cure – no pay principle, which means that our client does not bear any costs.

Our reliability is measured by customer satisfaction: our services are already used by thousands of industrial plants throughout Europe. To join them, contact us – we will be happy to answer all your questions.

Examples of electric motor repairs

Allen-Bradley. Repair of electric motors marked 1326AB, 1326AS, 1326AH, 8720SM, 8720MC. Repair of the MP series (including MPL low inertia motors and MPS servo motors), compact TL motors and high-power asynchronous motors from the HPK family.

Siemens. Comprehensive regeneration of electric motors 1FE, 1FT3, 1FT4, 1FT5, 1FT6, 1FT7, 1FK6, 1FK7, 1PH2, 1PH4, 1PH6, 1PH7, 1PH8, 1FW6, 2PS, 1PM4, 1PM6. Full testing capabilities for all listed models.

Indramat / Bosch Rexroth. Repair of synchronous MDD, MHD, MKD, MKE, MSK, MSM motors, MAD and MAF asynchronous servo motors, MAC series servo motors and many others.

SEW-Eurodrive. Repair of servo motors from CM, CT/CV, DS, DF series, BSF servo gears, PSC and PSF gearmotors, as well as CMS electrocylinders.

Yaskawa. Repairs of SGM electric motors and servo motors from the Sigma II, Sigma III, Sigma-5 and Sigma-7 series.

AMK. Repairs of DYNASYN DD electric motors (including DD5, DD7), DYNASYN DT high-torque motors and AMKASYN asynchronous servomotors (DS, DV, DH, DW).

Lenze. Repair of MCS synchronous motors and MCA, MQA, MDFQA, SDSGA asynchronous servo motors. Service of servomotors from the MDSK and MDFK families.

Parker Hannifin. Diagnostics and repair of the Parker HDX/HBMR electric motors, servo motors from the SMH/SMB, MH/MB, HDY/HJ series and SM, SE, BE series.

Schneider Electric. Rewinding of Schneider BSH electric motors. Repair of BCH, BMH, BRH servomotors. Service of Lexium BPH brushless motors and Lexium ILS 3-phase stepper motors.

We also have extensive experience in repairing motors from manufacturers such as: B&R, Baumüller, Emerson, Elau, Fanuc, KEB, Kollmorgen, Mavilor, Mitsubishi, Omron and Panasonic.