Industrial machine modernization

We provide modernization services for machines and production lines

We carry out works in the field of modernization of industrial machines and improve the efficiency of production lines. We offer, among others, modification and comprehensive replacement of control systems, replacement of old drive systems, HMI panels, modification of existing programs or creation of new visualizations. We determine the scope of modernization after performing an audit at the Client's, and after completing the work we prepare a complete set of documentation in accordance with the EU regulation 2023/1230 on machinery.

If you want to increase the efficiency of your machines, improve their safety and expand their functionality - you can count on our support. Thanks to the fact that we have advanced repair facilities, we will help you not only modernize the machine, but also maintain its individual components in excellent condition.

What does machine modernization at ADEGIS involve?

In our company we perform the following services in the field of machine modernization:

- Performing an on-site audit, verifying the Client's needs and determining the scope of modernization works.

- Modification and comprehensive replacement of machine control systems. Replacement of old type PLC with newer solutions (e.g. Simatic S5 → Simatic S7) along with code conversion.

- Expansion of machine functionality. Modification of an existing program, the purpose of which is to provide the Customer with greater possibilities without modifying the physical state of the machine.

- Replacing old drive systems with modern solutions. Replacing old inverters or servo drives with newer solutions (e.g. replacing Simovert, Simodrive, Micromaster with the Sinamics family).

- Selecting a drive system – replacing an existing motor that is no longer available on the market with a compatible and newer generation motor. Adjusting the control parameters in the servo drive/inverter.

- Increasing machine efficiency – modernization of programs aimed at increasing machine efficiency.

- Replacing the HMI panel with a newer/larger model, making a backup of parameters and adapting the existing project to the Client's needs.

- Creating and expanding visualizations on HMI panels.

- Backing up parameters of HMI panels, PLC controllers, inverters, drives.

- Diagnosing machine failures at the customer's site.

Upon completion of the work, we provide a complete set of documentation that the user should receive in accordance with EU Regulation 2023/1230 on machinery (formerly Machinery Directive 2006/42/EC). The scope of documentation depends directly on the scope of work performed.

You can count on our support at every stage of the process – from determining the scope of work needed to modernize the machine, to service support for replaced drives, panels and other components.

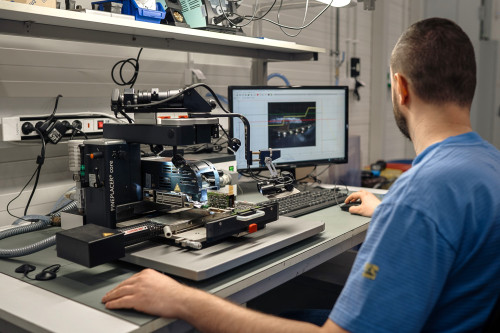

Our technical background

Machine Modernization – Case Study of a Cartoning Line

One of our key clients in the food industry, specializing in coffee production, was facing a number of issues on their cartoning line. Since these problems affected both efficiency and the comfort of the production team, a comprehensive machine modernization was necessary.

Our work included several stages:

- Replacing the HMI panel

- Developing a new visualization interface

- Introducing PLC program changes aimed at improving machine performance

The project we delivered improved line efficiency by 18%, and operating the machine became significantly easier and more intuitive.

Let's talk about your needs:

You may also be interested in:

Servo motor repairs | Sale of components | HMI repairs | Process data acquisition and analysis