Servo drive repairs

Comprehensive repairs of servo drives for industry

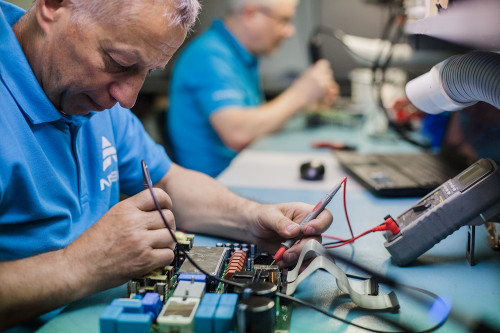

ADEGIS Automation Service specializes in the repair of drives and servo drives for industrial plants. We perform thorough diagnostics, repair and replace damaged components, clean and test drives of most well-known manufacturers.

We provide a free service estimate, efficient order processing and a 24-month warranty for the entire device. If necessary, we perform express repairs or on-site repairs (in Poland).

REMINDER: Our offer is aimed at businesses. We do not provide services to individual clients.

Repair of Fanuc servo amplifiers at ADEGIS

How to repair a drive in ADEGIS?

- Contact us via the inquiry form or by email at office@adegis.com.

- Send us your device for a free repair estimate.

- Accept the time and price offer that we will present to you.

Scope of work for drive repairs

Servo drive diagnostics. We start each repair by identifying the scope of damage the device has taken. We carry out diagnostics of the power supply module and executive modules based on IGBT transistors, MOSFETs or thyristors; as well as diagnostics of the measurement system and communication system. We perform voltage measurements and measure passive and semiconductor components.

Cleaning. Devices operating in difficult industrial conditions are particularly exposed to contamination and dirt. Therefore, we clean individual drive elements using ultrasonic cleaners, and then dry them in our industrial dryers.

Components repair and replacement. Depending on the need, we repair:

- power module,

- low voltage converter and DC bus power supply,

- analog and digital input/output modules,

- communication interfaces,

- measurement system,

- cooling system,

- regeneration of damaged laminate.

We replace fans and semiconductor and passive components. Each time we repair a device, a set of THT and SMD electrolytic capacitors is also replaced.

Testing the device. Thanks to the use of dedicated test stands, our servo drive service is characterized by high efficiency and a low complaint rate. We backup the client's parameters and then test the drive on a dedicated motor. We check the operation of all modules, the cooling system and the operation of the device under load.

If the extent of the damage does not allow for effective repair, we follow a strict no cure – no pay principle, which means that our client does not bear any costs.

Our reliability is measured by customer satisfaction: our services are already used by thousands of industrial plants throughout Europe. To join them, contact us – we will be happy to answer all your questions.

Examples of drive and servo drive repairs

- Repair of Siemens SIMODRIVE 611, SINAMICS S120, SIMOVERT MASTERDRIVES MC/VC servo drives;

- Repair of Indramat / Bosch Rexroth servo drives from the EcoDrive, IndraDrive, ANAX, DIAX series 01 / 02 / 03;

- Repair of AMK AMKASYN drives: AN, AW, AZ, KE, KW;

- Repair of Emerson / Control Techniques Digitax ST and Unidrive (M, SP) in servo mode;

- Repair of Kollmorgen servo drives from the SERVOSTAR 300 (S300) and SERVOSTAR 600 (S600) series;

- Repair of SEW-Eurodrive drives from the MOVIDRIVE, MOVITRAC, MOVIFIT families;

- Repair of Lenze 9300 and 9400 servo converters;

- Repair of the BSD series (Brushless Servodrives) from ABB;

- Elau PacDrive MC servo drive service;

- Repair of KEB COMBIVERT F5-SERVO regulators;

- Baumüller servo drive repair (BUM / BUS);

- Repair of Mitsubishi MR-J2 and MR-J3 servo amplifiers from the MELSERVO series;

- Repair of Yaskawa drives from the Sigma I, Sigma II and Sigma-5 families;

- Repair of Allen-Bradley (Bulletin 2098 Ultra 3000), Omron (R88M-G), Schneider Electric (Lexium 32) and other manufacturers.

Submit a request for quotation

You may also be interested in:

Inverter repairs | Servo motor repairs | HMI repairs | Industrial electronics sales