Industrial automation repairs

Industrial Automation & Electronics Repair

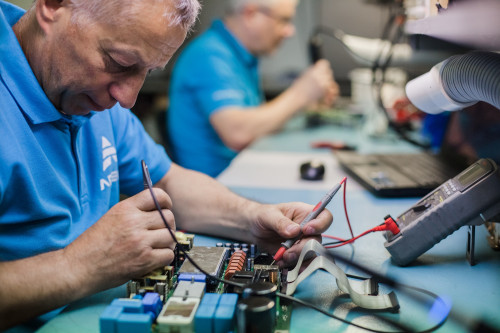

At ADEGIS, we provide industrial automation and electronics repair services for manufacturing plants across Europe. For over 15 years, we have supported Maintenance Departments by delivering reliable solutions that minimize downtime and extend machine lifespan, regardless of industry or technology.

We offer free repair estimates and a 24-month warranty on the entire device — regardless of the scope of the service performed. When needed, we also provide express repairs or on-site service at the customer’s facility (in Poland).

Industrial automation repair – what does it include?

We specialize in the repair and refurbishment of industrial automation equipment from most global manufacturers. The devices we service most often include:

Operator panels and HMI interfaces

We repair displays and touchscreens, replace or rebuild keyboards from scratch, perform software backups, and complete each repair with comprehensive functional testing.

Motors and servomotors

Every servomotor that enters our service undergoes detailed diagnostics (winding resistance measurement, insulation assessment, encoder/resolver testing). Our work includes everything from bearing replacement and rotor balancing to full paint restoration. We also rewind electric motors.

Drives and servo drives

We perform full diagnostics of drives and soft starters, including power, measurement, communication and cooling circuits. After cleaning and refurbishment, we replace worn components and then test the device under load using a dedicated motor.

Inverters and frequency converters

We repair both industrial inverters and photovoltaic inverters of various types: string, hybrid and off-grid. We diagnose faults using professional measurement equipment, repair or replace damaged components (IGBT transistors, capacitors, communication modules, etc.) and test all inverters on dedicated test benches.

PLC controllers

We repair industrial electronics in I/O modules, power supplies, CPU units, communication modules and other PLC control elements. We also offer a wide selection of new and refurbished spare parts, enabling fast restoration of your system.

CNC control components

We service CNC control systems, including control units, I/O modules, operator panels and more. We also support legacy systems that are no longer serviced by the manufacturer.

Industrial power supplies

Every device in our service goes through full diagnostics, repair and component replacement, followed by functional tests that simulate real industrial operating conditions. If a device cannot be effectively repaired, we follow our strict no cure – no pay policy, meaning the customer incurs no cost.

Why choose ADEGIS?

- 24-month warranty on the entire device

As one of the few service providers on the market, we offer a full warranty covering the entire device — regardless of the scope of the repair work performed. - No repair – no cost

You pay only for a successful repair. If the device cannot be restored to working condition, we refund your payment. - Support for out-of-warranty and discontinued equipment

We repair automation equipment that is no longer supported by the manufacturer, difficult to source or completely discontinued. - In-house workshops and dedicated test benches

All devices are tested under load on our own test stations, simulating real conditions on a production line. - Express turnaround times and fast quotation

We offer express and priority service options for critical Maintenance Department failures. - Access to new and refurbished spare parts

If needed, we provide industrial automation components directly from our spare parts warehouse — including both refurbished parts and brand-new items in factory packaging.

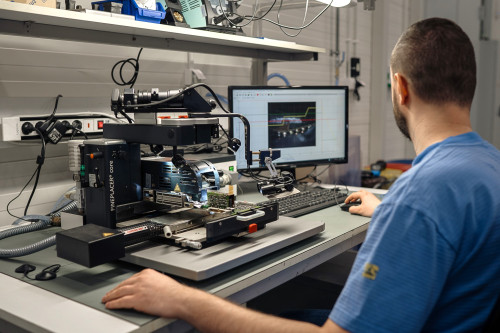

Advanced technical facilities – technology that ensures reliable industrial automation repairs

ADEGIS operates one of the most comprehensive service laboratories in Poland, equipped with technologies that enable precise industrial automation repair, electronics refurbishment and full functional testing under production-like conditions. This ensures high repair effectiveness and complete verification of each device before it is returned to the customer.

Our key service technologies

- Finetech Fineplacer Core BGA station – precision repair of BGA and SMD components.

- Bio-Circle biological cleaning systems – safe cleaning of motor components and mechanical assemblies.

- Ultrasonic cleaners and industrial dryers – thorough cleaning and drying of electronics.

- CIMAT dynamic balancer – accurate rotor balancing for servomotors.

- Blowtherm paint booth – restoration and protection of motor coatings after repair.

- Service dynamometer – load testing of motors and verification of performance parameters.

- Dedicated test benches for inverters, drives, motors, HMI panels and PLC controllers, accurately replicating production conditions. This includes stations for Siemens Simotics, Siemens Sinumerik 840D, GE Fanuc Series 18i, Elau PacDrive, Emerson UniDrive and Rexroth IndraDyn.

Every device repaired in our facility undergoes a complete cycle of functional and load tests, ensuring stability and readiness for operation in demanding industrial environments.

FAQ: Industrial Automation Services

Submit a request for quotation

You may also be interested in:

Inverter repairs | Servo motor repairs | HMI repairs | Industrial electronics sales